In this post, we will discuss the use of Ultra High Performance Concrete (“UHPC”) as a solution to bridge overlays and discuss a project where it was installed using ceEntek’s Next Generation UHPC 2.0TM.

As described in our previous posts, UHPC is typically recognized as a concrete with a compressive strength of at least 120MPa and consists of Portland cement along with various fine admixtures, such as well-graded sands. This combination of materials gives UHPC a much lower porosity and makes it more resistant to water penetration in comparison to Normal Concrete (“NC”) and High Performance Concrete (“HPC”). Additionally, steel fibers are added to increase ductility in the mix and enhance post-cracking tensile strength. This in turn can reduce the total amount of steel reinforcement needed on a structure and expand the uses of UHPC. One of these uses can be seen in bridge deck overlays during bridge rehabilitation projects.

A bridge rehabilitation project will often repair the existing deck rather than replace it with a new one. As such, some demolition of the top layer of deck to remove the current concrete in poor condition is required and usually done using milling or hydrodemolition methods. This is then replaced with a new overlaying layer (“overlay”) on top of the existing deck to add structural stability as well as protection to the underlying structure.

A bridge overlay is typically used in one of two scenarios:

In both of these scenarios, UHPC serves as an excellent solution due to its low porosity and higher tensile strength. As an overlay, the UHPC’s design is changed to incorporate more fiber and less water to obtain a thixotropic mix that will remain in place in any sloped surfaces while meeting all the needs for strength. ceEntek’s ce200SF-tTM thixotropic mix can be used in either of these scenarios as its Carbon Nanofiber technology (“CNF”) increases overall UHPC performance (i.e. bond to substrate, low shrinkage, and high tensile strength).

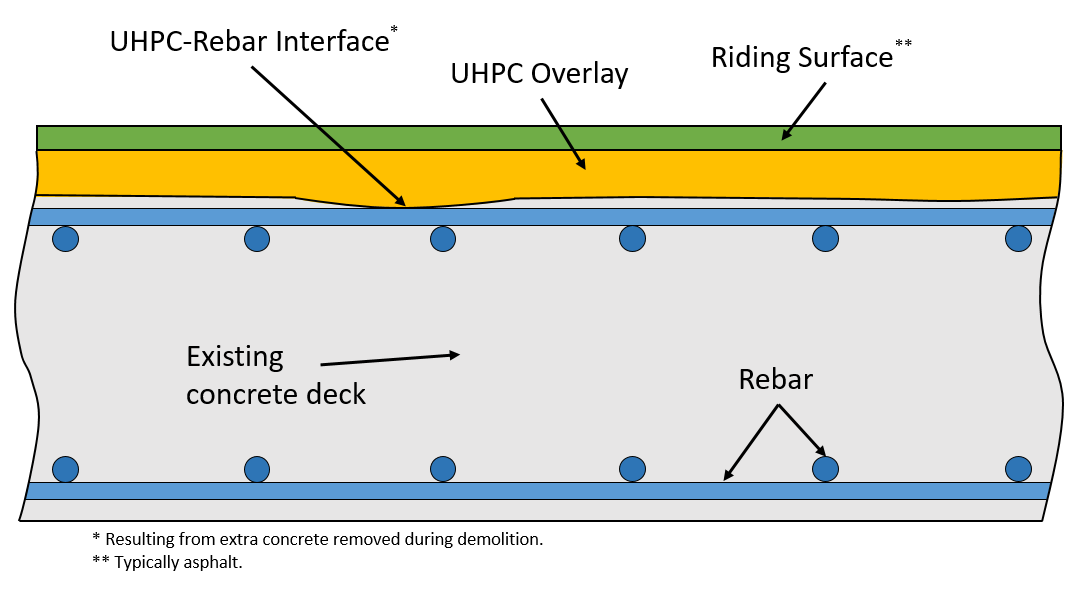

In this case, the UHPC will not serve as a riding surface but rather as a protective and structural layer between the new riding surface and the existing deck. This layer usually is 1-2in thick and will have a layer of asphalt, or other surface material, added on top to serve as the riding surface as shown below. Due to its longevity and high water resistance, UHPC is a perfect solution for this middle layer, as it will work to prevent any water damage to the lower parts of the deck. Additionally, the UHPC may limit future repairs to only the asphalt/riding surface, as the UHPC’s durability will reduce any corrosion and damage.

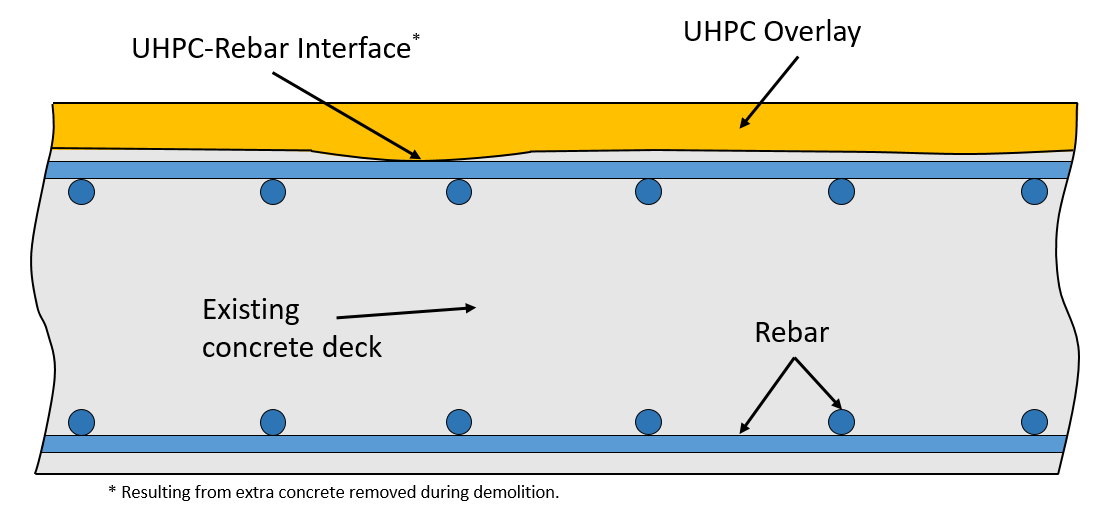

In cases where the overlay will become the riding surface, as shown in the figure below, a thicker layer is added on top of the existing deck. This layer may be over 2 inches thick and is grinded and grooved to ensure a smooth ride and a non-slip surface for traffic. As a concrete with higher tensile strength and low porosity, UHPC can be used as the final exposed overlay material in this scenario. The addition of steel fibers in the mix results in a surface capable of sustaining the live loads from everyday traffic and reduces the amount of cracking, which reduces water penetration and corrosion in the steel, thus improving its durability.

During the demolition process of the aforementioned scenarios, the hydrodemolition will remove any concrete in poor condition to reach layer of deck that is still in acceptable condition. This process, however, sometimes uncovers more concrete in poor condition than previously anticipated and in turn, the demolition will go deeper and expose the existing rebar in the deck. As such, it is important that the material chosen as the overlay have a strong bond to both concrete and steel to ensure proper structural stability in the deck and reduce any permeability at the joints.

ceEntek’s CNF design allows for the needed bond to both steel and concrete and its increased durability serves as the perfect riding surface. Due to this, ceEntek’s ce200SF-tTM has been previously used in various overlay projects including the I-88 rehabilitation project near Richmondville in Upstate New York.

Figure 3. I-88 UHPC Overlay with White Curing Compound

This project, located near Richmondville, New York, consists of the resurfacing of a large stretch of highway on I-88 between exits 19 and 21 along with the rehabilitation and replacement of various bridges. This highway serves as the main connection between the capital of New York, Albany, and the West side of the state. As such, it experiences large amounts of traffic, which along with winter conditions, has deteriorated the roads and bridges. Two of these bridges, located on exit 19 over Schenevus Creek, are designed to receive an UHPC overlay that will serve as the riding surface. The first of the overlays was carried out late August 2021 using ceEntek’s ce200SF-tTM mix.

Text BoxBefore the installation of the overlay, hydrodemolition of the existing deck surface was done to remove all of the deteriorated concrete. This method is preferred for overlays, as it ensures proper removal of all poor material as well as it roughens up the existing deck’s surface to create a better bond between the UHPC and the deck. After demolition, however, it was discovered that the poor condition of the concrete extended deeper into the deck than expected. As such, parts of the rebar became exposed adding the need to obtain a strong bond both rebar and existing concrete as well as increasing the overall depth and UHPC quantities required.

Utilizing a thixotropic mix, ceEntek’s technicians mixed and tested 72 batched totaling approximately 46.5cy. Each batched was individually tested for flow and quality control before being poured on the bridge and then spread manually using rakes. As UHPC overlays are thixotropic mixes with additional fibers, external vibration is required to liquefy the mix and turn into a self-leveling mix for a short time. After the vibration is removed, the mix returns to its thixotropic properties and remains in place. For this project, the UHPC was spread evenly using a vibrating screed spanning an individual lane. The ce200SF-tTM mix attained the necessary bonds and strength, and the resulting surface maintained the slope and level required as a riding surface.

This project, amongst others, demonstrate the capacity of UHPC being used as an overlay material. The fine aggregate and fiber content allow the mix to meet the necessary properties for casting in various surface bridge conditions. Additionally, ceEntek’s CNF design improves overall UHPC performance and results in concrete that is both durable and versatile.