Technology leadership

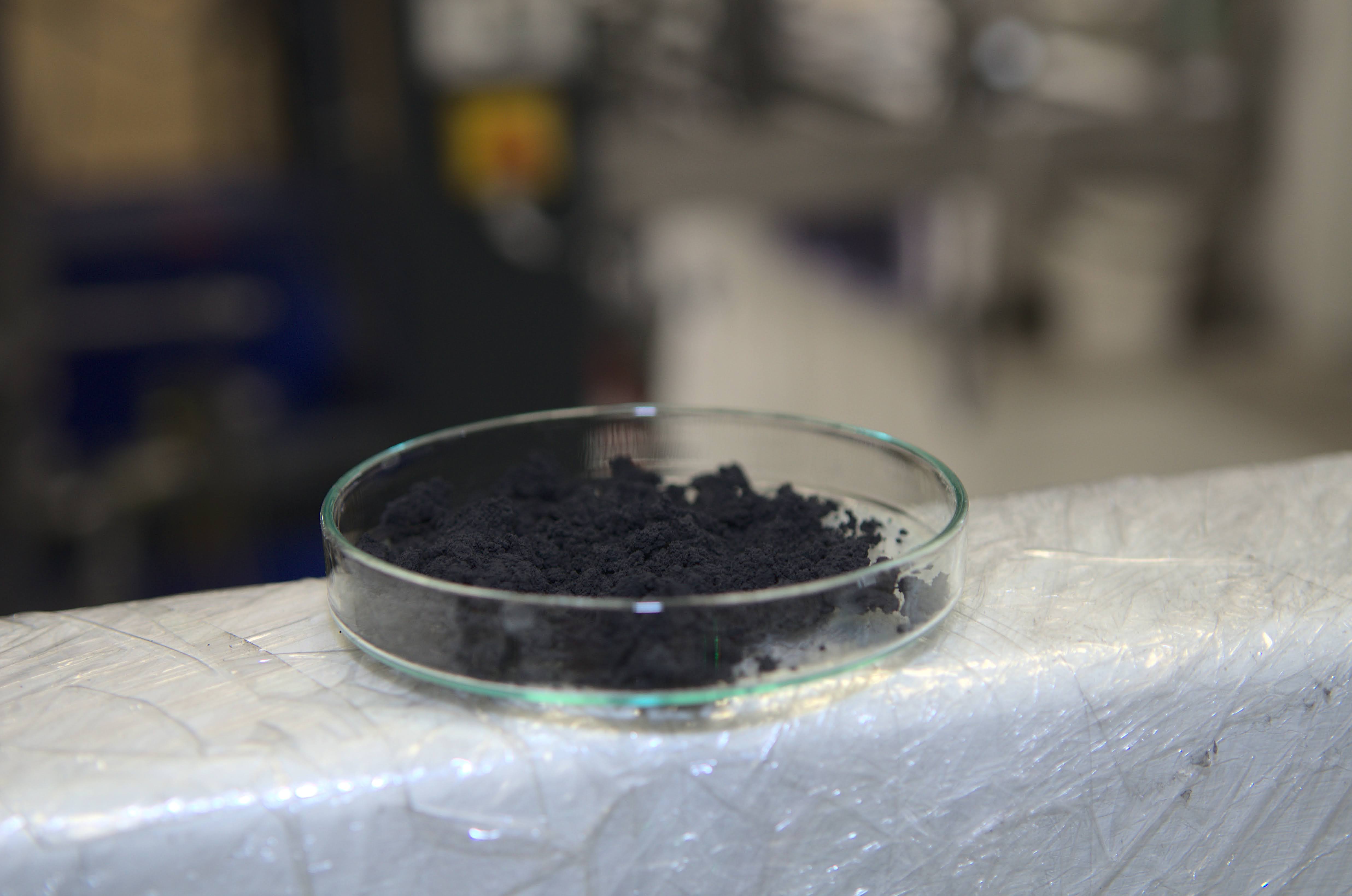

CNF-Production Since 2010, ceEntek has been producing functionalized carbon nanofibers (CNFs) optimized for high chemical and physical interaction with UHPC2.0TM. This is only possible because ceEntek was able to engineer and produce its own catalyst and use highly specialized reactors for industrial CNF production. Local Materials UHPC2.0TM is manufactured globally using the raw materials available … Technology leadership

Continue Reading