Windfarm grouting

ce200™ – 140G has been formulated to meet the most stringent requirements from foundation to transition piece grouting for offshore windfarm projects. The excellent load transfer capacity and extreme flowability combined with reduced shrinkage make it the material of choice for demanding grouting applications. Due to the elimination of coarse aggregates, ce200™ – 140G prevents damage to mixers, pumps and hoses.

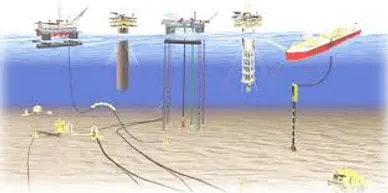

Floating structures

ce200LH™, available in a wide range of densities, allows the construction of medium to large floating platforms and structures. By eliminating traditional materials such as ferro-cement, structures’ lifetime will be extended and annual repair cycles will be limited. In combination with ce200™ composite structures can be produced, further increasing the durability of the resulting structure.

Protective coatings

Pending the specific structural requirements, ceEntek’s family of UHPC products provide the ideal solution for protective coating and strengthening of Offshore structures. All products for Offshore applications are based on ceEntek’s proprietary binder technology resulting in sulfur resistant, long lasting solutions.

Repair/Jacket Strengthening

Repairs with ce200™- 120G grout can be performed in a short time-span avoiding production interruptions of Offshore Oil and Gas platforms and Assets. ce200™- 120G is the ‘all-around’ repair grout solution for small to large repair and reconstruction projects. It provides the strength, non-permeability, chloride protection for the repair of concrete and steel structures. Due its dense structure it prevents further oxidation and corrosion of the underlying structure extending the lifetime of the structure for many years to come.

Subsea stabilization

ceEntek designed a range of concrete solutions ideal for subsea cable stabilization, pipeline stabilization, buckle initiator footing and many others. Its non-shrinkage, high performance concrete grouts are engineered specifically for applications in harsh offshore conditions to ensure process reliability and effectiveness. ceEntek’s concrete family of products for offshore stabilizations has a density range of 1,400 – 2,400kg/m3 and has no water carrying capillaries which makes it ideal for uses in concrete mattresses, prefilled grout bags, and grout pillows.

Offshore P&A

Plug-and Abandonment of wells is a rapidly growing market. Here, low cost combined with reliability of the solution are the key factors. As borehole and well conditions differ in a wide range, P&A cementing needs to adjust accordingly. ceEntek offers the range of products and know how allowing an optimized and cost effective solution for well cementing.